Products

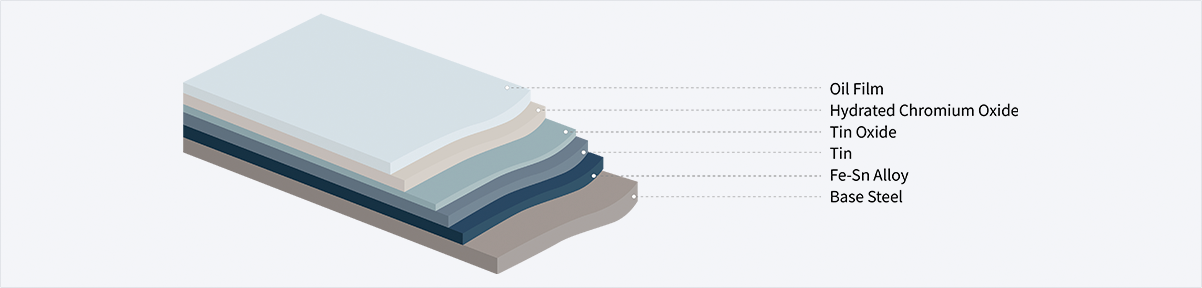

Tinplate (ETP)

Product Catalog

F&B storage / Aerosol / General cans / Paint Cans 14L, 18L / Electronic components

Product standard code

| Standard | KS | ASTM | JIS | EN |

|---|---|---|---|---|

| Code | D 3516 ET | A 624 | G 3303 SPTE | 10202 |

Coating weight (unit : g/m²)

| Symbol | Nominal coating weight | Minimum average coating weight | Minimum coating weight of 1point |

|---|---|---|---|

| 1.0 (#10) | 1.0 | 0.85 | 0.75 |

| 1.5 (#15) | 1.5 | 1.35 | 1.20 |

| 2.0 (#20) | 2.0 | 1.80 | 1.70 |

| 2.8 (#25) | 2.8 | 2.45 | 2.25 |

| 5.6 (#50) | 5.6 | 5.25 | 4.99 |

| 8.4 (#75) | 8.4 | 7.85 | 7.46 |

| 11.2 (#100) | 11.2 | 10.10 | 9.60 |

Oil weight (unit : mg/m²)

| Symbol | Aim | Application |

|---|---|---|

| D - 1 | 4.5 | Printing, Lacquering |

| D - 2 | 8.0 | For plain |

| D - 3 | 12.5 | For plain |

| D - 4 | Max 20 | Special usage |

Chemical treatment (unit : mg/m²)

| Symbol | Treatment | Aim | Application |

|---|---|---|---|

| None | None | None | 2-Piece Can |

| 300 | Sodium Dichromate Dip | 1.6 | Food can(Mushroom) |

| 311 | Cathodic Sodium Dichromate Low Coulombs | 4.0 | General can, Food/beverage can |

| 314 | Cathodic Sodium Dichromate High Coulombs | 10.0 | Special usage |

Base Steel Standard Code

| Code | KS | ASTM | JIS | EN |

|---|---|---|---|---|

| Code | D 3516 SPB | A 625 | SPB | 10202 |

Classification

① Classification by Type of Steel

| Type of Steel | Remark |

|---|---|

| MR (Medium Residual) | It contains few residual minor constituents and it is widely used for applications such as containers. |

| L (Low Metalloid Steel) | It contains particularly few residual minor constituents such as Cu, Ni, Cr, Mo, so that it is suitable for the materials of containers required improved corrosion resistance. |

| D (Drawing) | It is aluminum killed steel, so that it is suitable for the applications, which bear deep drawing, or other working that is liable to produce Luder’s lines pattern. |

② Classification by Temper

The temper grade of SR(Single Reduced) BP(Black Plate) shall be expressed by the Rockwell superficial hardness values(HR30Tm)

| Symbol | t ≤ 0.21mm | 0.21mm < t ≤ 0.28mm | t > 0.28mm | Remark | |

|---|---|---|---|---|---|

| T50 | T1 | ≤ 53 | ≤ 52 | ≤ 51 | Deep Drawing, Aerosol |

| T52 | T2 | 53 ± 4 | 52 ± 4 | 51 ± 4 | Battery case |

| T55 | T2.5 | 56 ± 4 | 55 ± 4 | 54 ± 4 | 18L liquid |

| T57 | T3 | 58 ± 4 | 57 ± 4 | 56 ± 4 | General Can |

| T61 | T4 | 62 ± 4 | 61 ± 4 | 60 ± 4 | General Can, Crown |

| T65 | T5 | 65 ± 4 | 65 ± 4 | 64 ± 4 | Food Can Top/End |

The hardness of less than 0.21mm in nominal thickness is normally tested using Rockwell 15T scale and results converted to Rockwell 30T scale.

- The temper grade of DR(Double Reduced) BP(Black Plate) shall be expressed by the Rockwell superficial hardness values(HR30Tm) or 0.2% average Yield Strength.

| Symbol | Average Rockwell superficial hardness | 0.2% average Yield Strength | Remark |

|---|---|---|---|

| DR450 | 68 ± 4 | 450 ± 70 | Aerosol, Food beverage Can |

| DR520 | 72 ± 4 | 520 ± 70 | Aerosol, Food beverage Can |

| DR550 | 73 ± 4 | 550 ± 70 | Aerosol, Food beverage Can |

| DR580 | 74 ± 4 | 580 ± 70 | DRD, Food beverage Can |

| DR620 | 76 ± 4 | 620 ± 70 | DRD, Food beverage Can |

③ Classification by Surface Finish

| Product | Designation | Symbol | Remark | Aim (Ra/㎛) |

|

|---|---|---|---|---|---|

| KS/JIS | TCC | ||||

| Single Reduced SR |

Bright Finish | B | BF | Blackplate finished to have a smooth surface with the use of temper-mill work rolls that have been ground to a low roughness | 0.20~0.40 |

| Stone Finish | R | RX | Blackplate finished to have a directional pattern with the use of final-mill work rolls that have been ground to a higher level of roughness than those used for the bright finish | 0.38~0.58 | |

| Silver Finish | S | D7 | Blackplate finished to have a dull surface with the use of temper-mill work rolls with dull surface texture(Electrolytic tinplate with a luster finish provided by a flow-melted tin coating) | 0.70~1.30 | |

| Matt Finish | M | D7 | Blackplate finished to have a dull surface with the use of temper-mill work rolls with dull surface texture(Electrolytic tinplate with a luster finish provided by a flow-unmelted tin coating) | 0.70~1.30 | |

|

Double Reduced DR |

Stone Finish | R | RD | Blackplate finished to have a directional pattern with the use of final-mill work rolls that have been ground to a higher level of roughness than those used for the bright finish | 0.25~0.45 |